Moving Targets

PolyWorks® helps preserve GE’s power plant output

Extreme Fab, Inc. is a structural metal fabrication company that has the tools and skills to build the massive machinery that the oil and gas, power, energy, and trucking industries require. One of their key customers is GE Aero Energy. GE Aero Energy gives businesses and communities around the world the ability to generate reliable and efficient power at or near the point of use, at any time—on or off the grid.

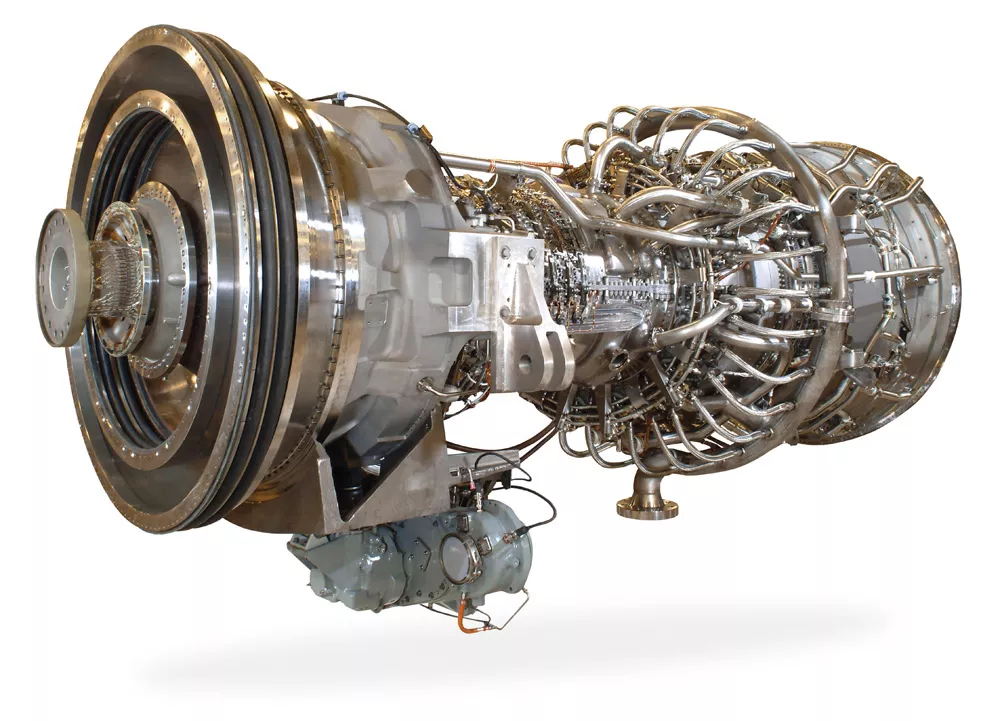

Using a wide variety of fuels, GE Aero Energy’s FlexAero LMS100 aero-derivative gas turbine generates up to 100 megawatts of electricity at a conversion efficiency of 44%. Made for rapid deployment and installation in isolated locations, such as remote villages, drilling sites, or disaster areas, this exceptional turbine is a power plant in a box. The LMS100 package includes the turbo, gas turbine, and compressor, all mounted and pre-assembled. To make this sophisticated piece of engineering work, it uses a large, high-precision skid.

When it comes to machining skids for GE Aero Energy, Extreme Fab partners with Dimensional Engineering, which provides 3D digital data capture, engineering, and analysis services to address design and production engineering challenges across a broad range of industries and applications.

The LMS100 aeroderivative gas turbine supplies up to 100 megawatts of electricity.

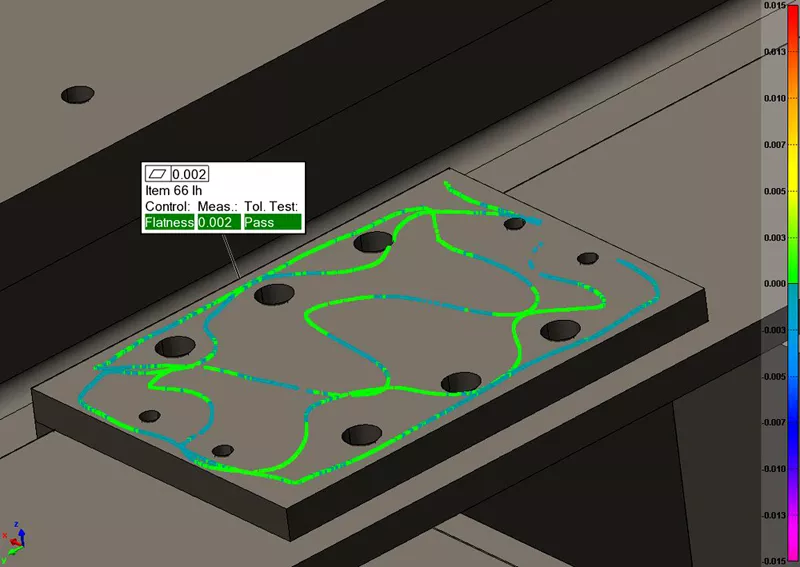

Rendering of the 60 x 25 foot, precision-machined skid. Bearing surfaces (green) are machined to +/- 0.002” flatness.

“It costs thousands of dollars just to ship the skid one way, so if it has to come back to Extreme Fab for reworking, there can be tens of thousands of dollars in additional transportation costs alone”

Machinists make adjustments to the one-ton field machining system.

The Challenge

Measuring 60 feet by 25 feet, the LMS100 skid has precisely machined bearing surfaces and mounting holes. The slightest machining deviation can decrease the power plant’s operational efficiency, energy output, and service life. According to William Bonner, Managing Director of Dimensional Engineering, “Mounting pads require a flatness of +/- 0.002" and elevations held to +/- 0.005", relative to all locations across the skid’s 60-foot length .”

Machining a large object to that precision is no easy feat, but the skid is even more challenging. “This thing moves; it’s never static,” said Bonner. One-ton field machining systems sit on the skid while making the precise cuts. “Every time you place the mill on the skid, it flexes because the mill’s weight is not distributed equally.”

Throughout the 10-day, 12-hour-a-day project, machinists relocate the equipment , causing the mounting pads to rise, fall, twist, and turn.

Thermal expansion is also a factor that further complicates matters. With considerable temperature variations of up to 50°F (10°C) over a 24-hour period, the skid expands and contracts throughout the day.

“Dimensional Engineering’s role is to control the setup and dictate cutter angles and depths so that Extreme Fab can deliver the precision that GE demands,” said Bonner.

If the skid arrives at GE and it doesn’t meet the required specifications, there are often dire consequences . “It costs thousands of dollars just to ship the skid one way, so if it has to come back to Extreme Fab for reworking, there can be tens of thousands of dollars in additional transportation costs alone,” Bonner explains. If reworking impacts production schedules, non-conformance can also mean significant financial penalties.

The Solution

With every machine move, before each cut and after each operation, Dimensional Engineering provides Extreme Fab precise measurements for mill placement, cutter position, and the position of the work-piece relative to the skid’s static, relaxed state. Without this measurement control, GE’s specifications would be tough, if not impossible, to meet.

Bonner said that his tools of choice are FARO laser trackers and InnovMetric’s PolyWorks|Inspector™ software solution. “We use the laser trackers to capture precise measurements and PolyWorks® to study and manage the data collected to direct the ever-changing project,” said Bonner.

Bonner’s two-man team starts with a basic alignment of the skid in its relaxed state. Using 50 reference targets welded to the work piece, the laser tracker measures the datum features of the skid and PolyWorks is used to create a world coordinate system. PolyWorks is then employed to establish multiple local coordinate systems that allow the team to isolate movement on an individual mounting pad while maintaining the relationship to the entire skid.

“If we couldn’t control the measurements considering the tracker repositioning,

there would be big problems.”

After positioning and levelling the mill, Bonner’s team measures the skid and the position of the cutter to provide exact locations that machinists use to program the cut depth and angle. When the operation is complete, measurements are taken once again to verify the cut prior to making another pass.

Since the skid changes with temperature, the Dimensional Engineering team processes all measurement data using the dynamic Temperature Compensation functionalities that PolyWorks offers. This adjustment, combined with the exact location of the machined feature, allows the machinists to program cutter paths relative to the skid in a stable temperature condition rather than its current, dynamically changing position.

Due to the skid’s size and line-of-sight considerations, the FARO laser trackers are repositioned dozens of times over the 10-day project. This introduces yet another variable to the precise machining operation. To make sure that all measurements are precise relative to all tracker positions, Bonner’s team uses PolyWorks’ move device and real-time bundling. As Bonner states, “If we couldn’t control the measurements considering the tracker repositioning, there would be big problems.”

To finish the project, a final inspection is conducted to confirm that the skid meets GE’s specifications. “We validate and certify every measurement, both during the project and before the shipment,” concludes Bonner.

Final inspection results confirm flatness on a mounting surface.

The finished skid being prepared for transport to GE.

The Benefits

“Without the use of the laser tracker and the PolyWorks|Inspector solution, there would be no way to achieve this level of accuracy and precision, at least not in a quantifiable way,” said Bonner. “We have been doing this work for six years and have worked on more than 50 skids. None of them have had to make that expensive round trip for rework.” In those six years, Dimensional Engineering has had only two non-conformance reports (NCRs): One was for a single out-of-spec hole, and the other was because of conflicting specifications in the skid’s drawings.

Dimensional Engineering applies the same process and tools to other large-scale projects, including auxiliary components for the LMS100 package, such as the intercooler. “The skid techniques are used to position two 50-foot radiator mounting rails while they are being welded, 120 holes on the radiator mounting flange, and parallelism on intake and output flanges,” explains Bonner. “Without precision measurements that we obtain from the FARO laser tracker and PolyWorks, the radiator would not fit in the intercooler, and the intercooler would not seat properly with the LMS100 turbine.”

With PolyWorks, Dimensional Engineering makes moving targets manageable and large-scale machining predictable.