Model-Based Definition for Measurement Planning

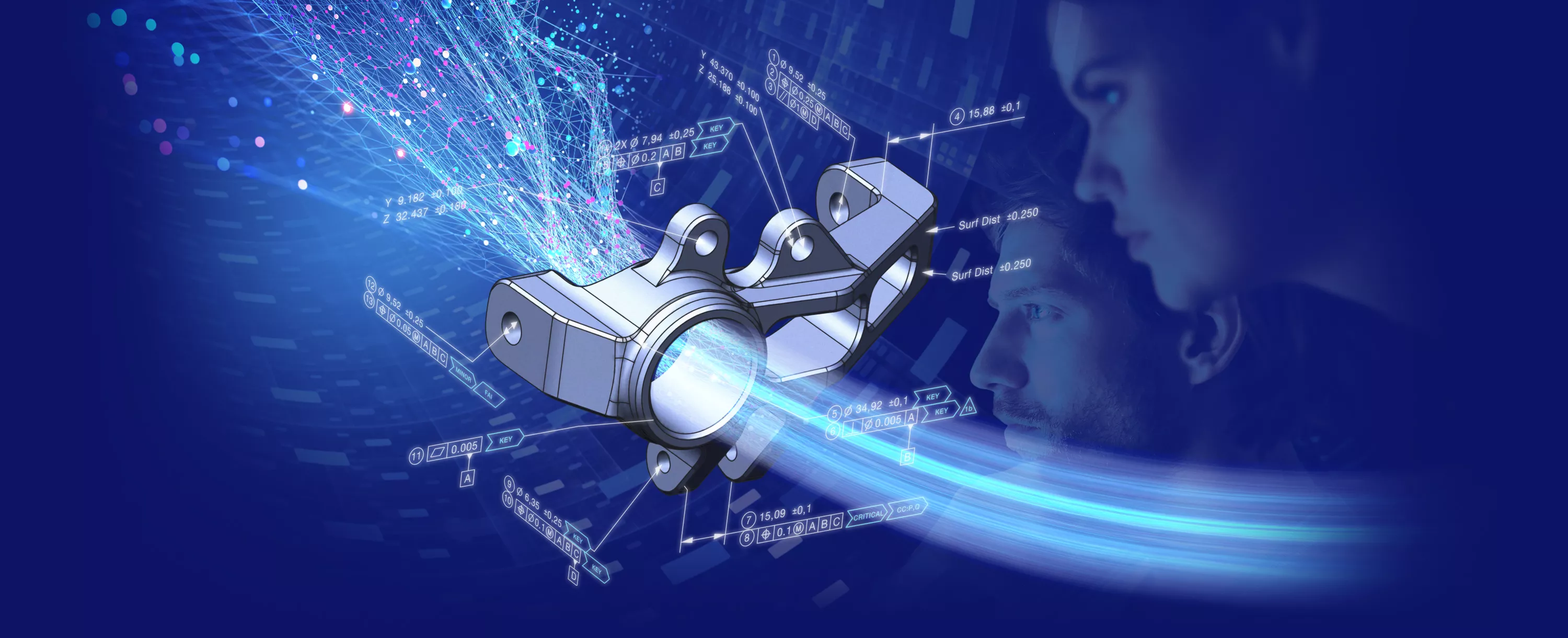

Master Modern 3D Measurement Planning

Model-Based Definition for Measurement Planning

Master Modern 3D Measurement Planning

Each company has its own recipe for sharing dimensional requirements, which may consist of encoding them within any combination of CAD models, product manufacturing information (PMI) and comma-separated values (CSV) files, 2D drawings, bills of characteristics documents, and more.

Upon reception, the quality control team spends precious time finding the information they need, translating and adapting design intent to their processes and software platforms while trying to avoid transcription and interpretation errors. Additionally, when a design change is made, extraordinary efforts must be deployed to correctly update their processes and documentation.

This white paper highlights the strong points, issues, and limitations of the 2D drawing and MBD-based approaches used by organizations today to share design and manufacturing dimensional requirements with quality control teams.

It explains how the digitalization of the 3D measurement planning process addresses existing shortcomings to significantly improve efficiencies, transforming this essential function from a burden into an asset.